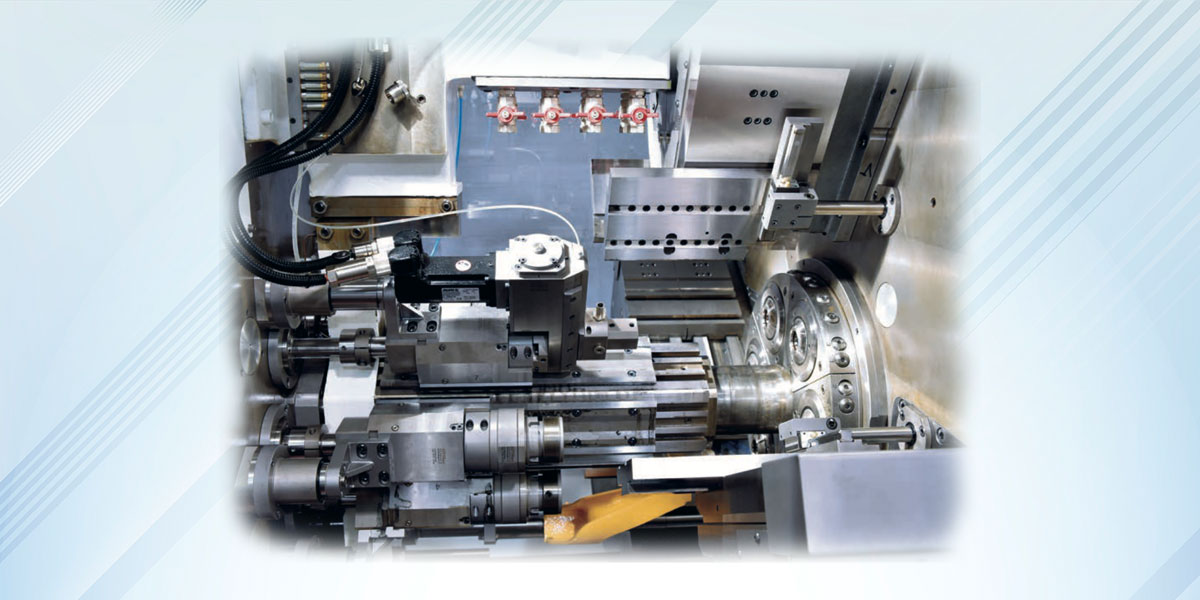

Multi-spindle Automatic Lathe

Summary: Multi-spindle automatic lathe, suitable for high-precision and high-volume production, one machine equals 6-8 single-spindle lathes, low unit processing cost

Industry Applications

Multi-spindle automatic lathes are widely used in the following industries:

- Automotive Parts: Efficient processing of various precision components.

- Sanitary Hardware: Meeting requirements for complex shapes and high precision.

- Refrigeration Industry: Suitable for high-volume production needs.

Core Advantages

- Multiple Bar Stock Processing: Significantly improves production efficiency.

- High Precision: Ensures dimensional and geometric tolerances of processed parts.

- High Automation: Reduces manual intervention and lowers production costs.

Features

- Efficient Production: Multi-spindle design enables continuous processing.

- Stable and Reliable: Advanced control system ensures stable equipment operation.

- High Flexibility: CNC multi-spindle lathes are suitable for small-batch processing of diverse parts.

Multi-spindle automatic lathes are indispensable high-efficiency equipment in modern manufacturing, providing more efficient and precise processing solutions for various industries.