Offline Simulation Programming for Robot CNC Band Saw Machine

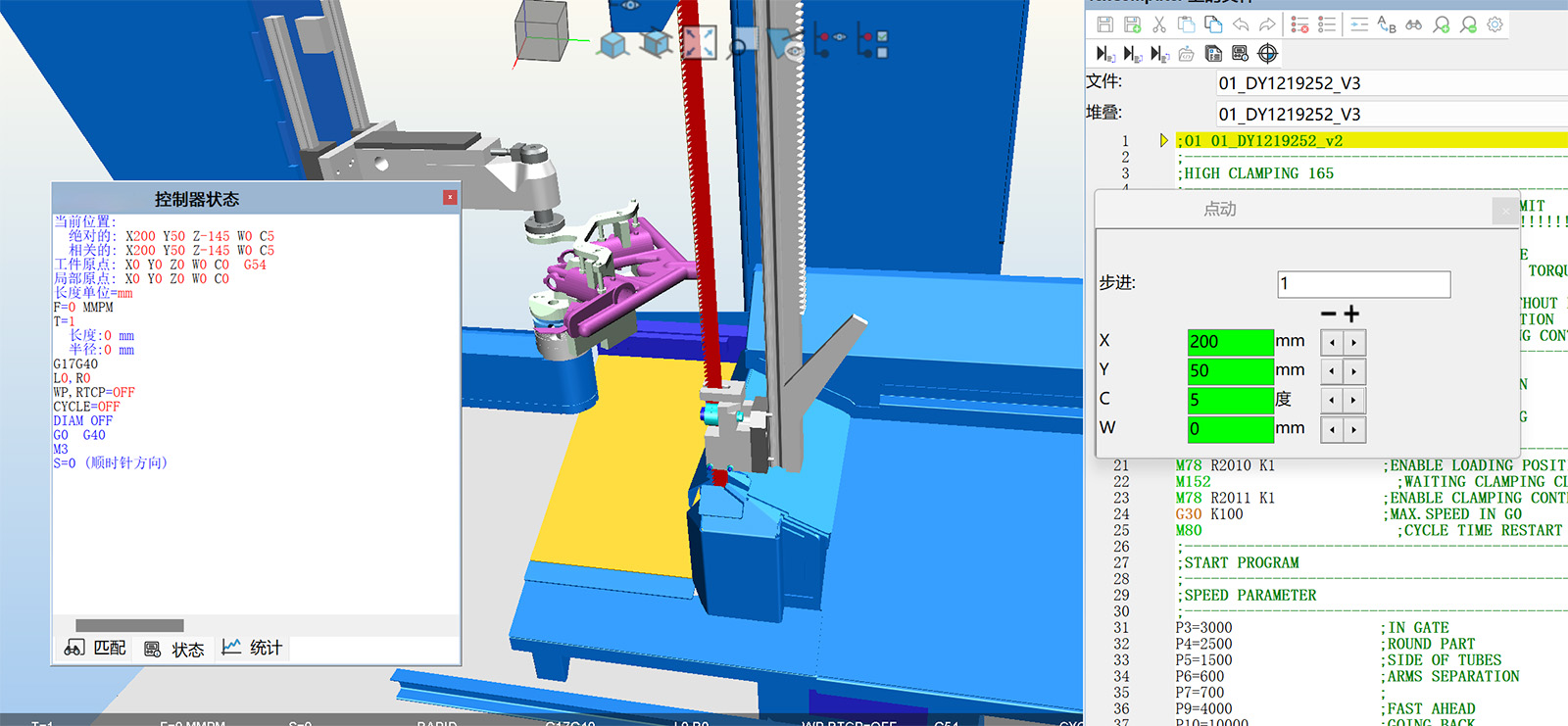

In precision sawing, the real efficiency battle has shifted from the physical shop floor to the virtual simulation space. Our Robot CNC band saw machine ships with a simulation system. By parsing the machine’s core configuration files, we reveal how “virtual drives reality” to guarantee safe and highly efficient offline programming.

Product Link: Visit our Robotic CNC Band Saw Machine product page

Italian Engineering & Localized Domestic Alternative

Our control algorithms and sawing process path design draw on established Italian industrial practices, then are fully localized for China foundry conditions (materials, fixturing, and on-site operation). The core hardware and control architecture support domestic alternatives that achieve performance parity with comparable Italian equipment while optimizing procurement and maintenance costs—an application-ready, high–value alternative for domestic deployment.

1. Axis Parameter Synchronization: True G-code Physical Drive

Unlike path-only simulators, our system runs on controller-level logic.

- Full axis mapping: Precisely defines every dynamic parameter from the base (BASE) to X/Y/W linear axes and the C-axis rotation axes.

- Physical constraints: The simulation synchronizes travel limits, feed rates, and C-axis extremes with the real machine.

- Native G-code parsing: Reads and parses CNC programs in

.isoformat, including coordinate systems like G55.

Value: What you see on the PC is the robot’s true motion feedback, eliminating the “smooth in simulation, error on the machine” problem.

G-code cutting program example:

; Main program start

;---------------------------------------------

; Cutting speed parameters

P5=1600 ; Riser cutting

P6=1900 ; Gate cutting

;---------------------------------------------

; Travel path

G0 X 225 Y-250.0 C-45 W 370

G0 X-127 C-90

S800

G0 Y-105

FP5

G1 Y-50

G1 Y-20

FP5

G1 Y 110

G0 X-135

G0 Y-185

; Riser 1

G0 X-32.5 Y-173 C-82.3

FP6

G1 Y-119

M50 K35 ; Turn on chip conveyor

G0 X-85 Y-235

2. Collision Monitoring: Virtual Armor for Your Equipment

Sawing is complex because the bandsaw blade closely interacts with guides and fixtures. Our system applies strict physical detection.

- Dynamic interference check: High-precision 3D models for the base, guides, and fixtures.

- High-precision tolerance: Collision detection at 0.01 mm. Even tiny grazes trigger a red warning instantly.

- Critical component protection: Special safety logic between the blade and workholding to prevent fixture damage.

Value: Collision risks are blocked 100% on the computer, protecting your expensive robot arm.

3. Real-Time Cutting Simulation: Dynamic Scrap Management

Our offline simulation supports real-time material removal, making the process transparent.

- What you see is what you get: Load

.STLmodels of workpiece and fixtures; the system computes and displays riser/gate cut-off effects from your G-code. - Scrap real-time computation: “Scrap wiping” logic shows removed material and whether it interferes with subsequent cycles.

- Process optimization: Monitor feed direction and tune entry angles in simulation to extend blade life.

Value: No trial cuts; first piece passes. Significantly lowers scrap rates for high-value brass and similar materials.

4. Offline Development: A Production Efficiency Multiplier

- Parallel engineering: While the line processes Order A, engineers program and debug Order B using simulation configuration files at the desk.

- One-click deployment: After validation, upload the program directly to the saw’s control system—no re-teaching—plug and play.

Value: Shortens new product development cycles and keeps equipment in a high-output, profitable state.

Technical Summary

We deliver not only a Robot CNC band saw machine but also a complete offline programming system based on digital simulation. If you demand extreme machining accuracy and production flexibility, choose our dedicated virtual simulation programming suite.