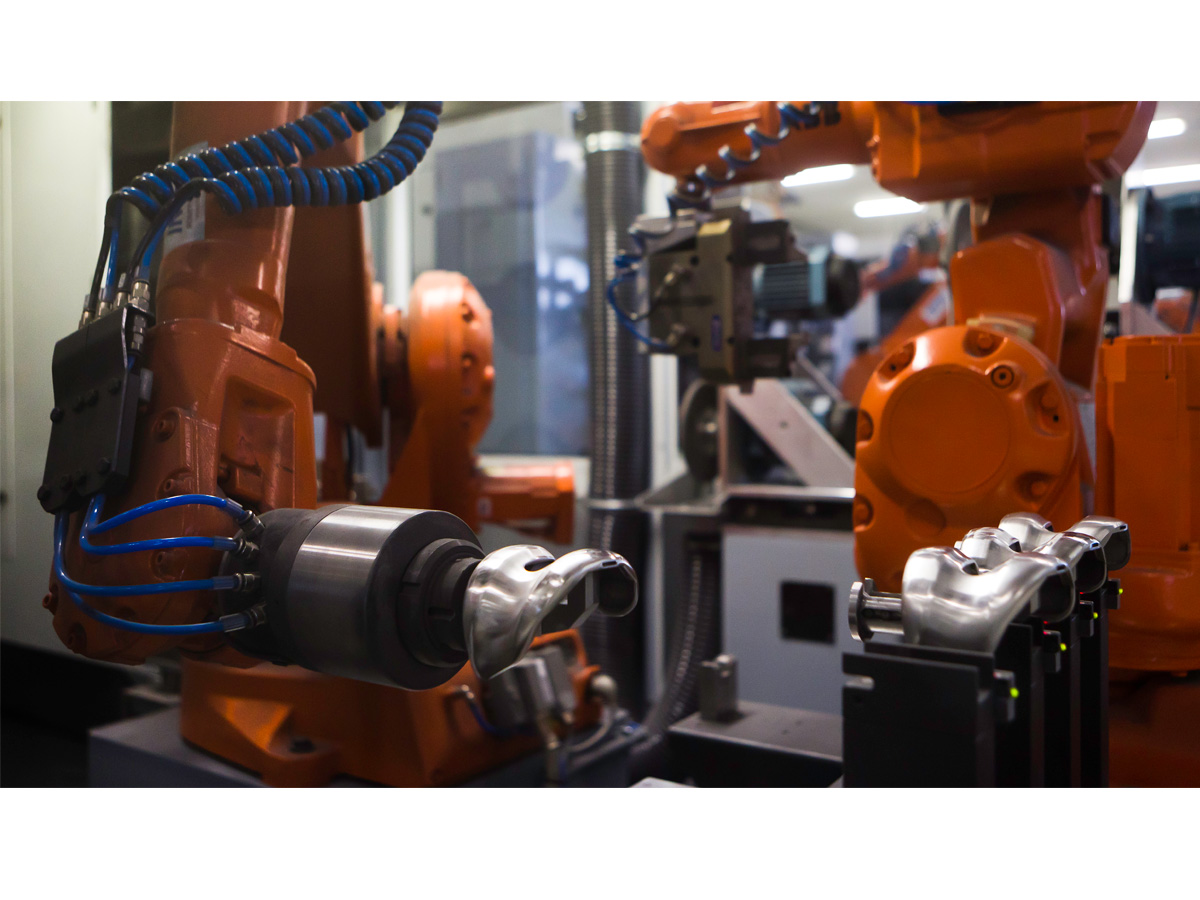

INTEC Robotic Polishing Cell for Knee Joints

Automated robotic cell designed for knee joint grinding and polishing. Integrated with ABB robots, INTEC precision grinding equipment, and advanced calibration software, achieving seamless transition from offline programming to production, significantly improving efficiency and consistency.

Key Advantages

Technical Specifications

Applications

Detailed Features

Dual Robot Collaboration

Equipped with one ABB IRB 2600-20/1.65 (20kg payload) and one ABB IRB 4600/45 (45kg payload) 6-axis robots, collaborating efficiently to handle complex workpieces.

Intelligent Grinding System

Includes two 3-belt grinding stations with automatic pressure compensation for belt wear, plus safety limit switches for belt breakage and contact wheel protection.

Efficient Polishing Unit

Integrates one INTEC PH1000 single-axis polishing head, one PH1000/2 dual-seat polishing head, and a nylon wheel combination unit to cover all fine polishing needs.

Advanced Calibration Software

INTEC's proprietary calibration software allows programs to be transferred seamlessly between cells. Factory relocation or new machine deployment requires only recalibration, with no program modification needed.

Automated Compound Supply

Features three liquid polishing compound feeding devices with mounting fixtures, solenoid valve assemblies, and 2 storage tanks for precise automatic compound replenishment.

Complete Cell Config

Includes three common base platforms, four loading/unloading stations, one workpiece transfer station, two repositioning stations, and two main electrical control panels.