What is an Escomatic (ESCO) Swiss-Type Automatic Lathe?

In the 1940s, Willy Rosetti, a Swiss parts manufacturer, encountered a burr problem while producing a watch part. The traditional radial feed cutoff tool he was using would create burrs that required secondary processing. To solve this problem, Willy proposed a new turning concept, which became known as the ESCO process and later developed into the ESCOMATIC machine tool product line.

💡 Product Recommendation: Our ESCOMATIC-type Y2-CNC Automatic Lathe adopts ESCOMATIC's tool head and straightening feed construction technology, offering better value for money compared to ESCOMATIC's D2 CNC model. For details, please visit our ESCOMATIC-type Automatic Lathe Y2-CNC product page.

Working Principle

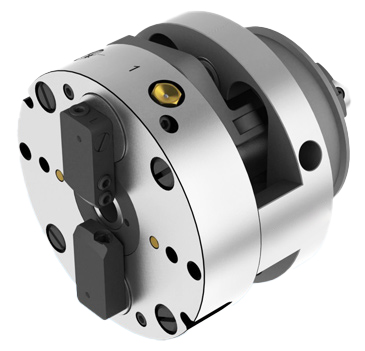

Swiss ESCOMATIC machine is a Swiss-type automatic lathe where the toolhead rotates around the material. Unlike traditional sliding head lathes, the material (coil stock) in ESCOMATIC machines doesn't rotate. The Escomatic process reverses traditional turning by 180 degrees. Cutting tools are mounted on the toolhead, which rotates around the material to machine parts. When the toolhead rotates, two to four tools simultaneously feed into the stationary material to machine the designed parts.

Technical Features

The machine's tools can be controlled by cams or CNC. Depending on the model, maximum toolhead speeds can reach 8,000 to 12,000 RPM. The tool holder uses curved rather than straight radial feed motion to overcome centrifugal force at high speeds. Tools are set very close to the workpiece, reducing non-cutting time.

ESCOMATIC Automatic lathes typically feature a rotary straightener. For materials not exceeding 6mm in diameter, the coil stock needs straightening before entering the rollers and guide bushing. The straightener rotates around the material, achieving bending and straightening through three-directional movement. After machining, a counter collet grips the finished part for parting off. This step produces flat, clean end faces, eliminating the need for secondary processing to remove burrs typical in traditional parting operations.