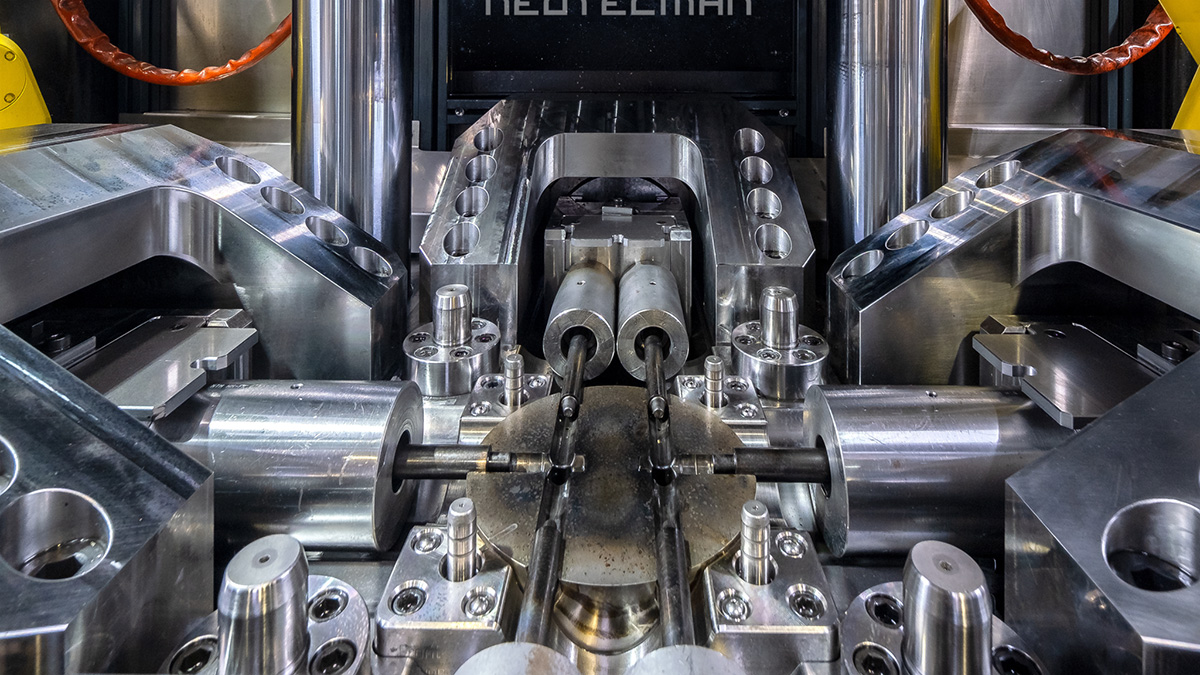

Neotecman Automatic Hydraulic Forging System: A Revolutionary Forging Production Method

Once you start using the Neotecman hydraulic forging system, your traditional forging production method will be completely transformed. This advanced equipment thoroughly solves the tedious problems in traditional forging processes where blanks need to be pre-cut and fed into furnaces and presses. Neotecman equipment automatically completes the entire process of heating, cutting, and feeding, and more importantly, since the finished forgings have no flash, it completely eliminates the hassle of flash removal, saving both brass material and labor costs.

Revolutionary Forging Concept

The Neotecman forging system is based on a simple and efficient working principle: just place a 1-ton or more, 4-meter long brass bar in the feeding rack, and it automatically produces completely formed forgings. Operators who have used Neotecman equipment are unwilling to return to the arduous working mode of traditional presses. The entire process is controlled through a simple and user-friendly interface, requiring only 30-40 minutes for product changeover. Once parameters are set, the equipment can run fully automatically without human intervention.

Advantages of Fully Automatic Integrated Forging System

- Simplified Production Process: Achieves one-stop processing from raw materials to finished products

- Flashless Technology: Completely avoids tedious blank billet cutting and flash removal steps in traditional forging

- High Automation: Fully automatic heating, cutting, and feeding system

- Quick Change-over: Only 30-40 minutes needed for product changeover

- User-friendly Interface: Simple and intuitive control system

- Fully Automatic Operation: No manual intervention needed after setup

Applications

This innovative hydraulic forging system is suitable for forging various aluminum and brass parts, making it an ideal equipment upgrade solution especially for manufacturing enterprises pursuing high efficiency, high precision, while aiming to reduce labor and material costs.

Customer Feedback

According to widespread customer feedback, factories that have used the Neotecman automatic hydraulic forging system never want to return to traditional forging equipment. This "unforgettable" experience is mainly due to the system's high efficiency, easy operation, and excellent product quality.

If you are looking for a solution to improve forging production efficiency, save labor and material costs, and enhance product quality, the Neotecman automatic hydraulic forging system is undoubtedly your best choice.